Main services

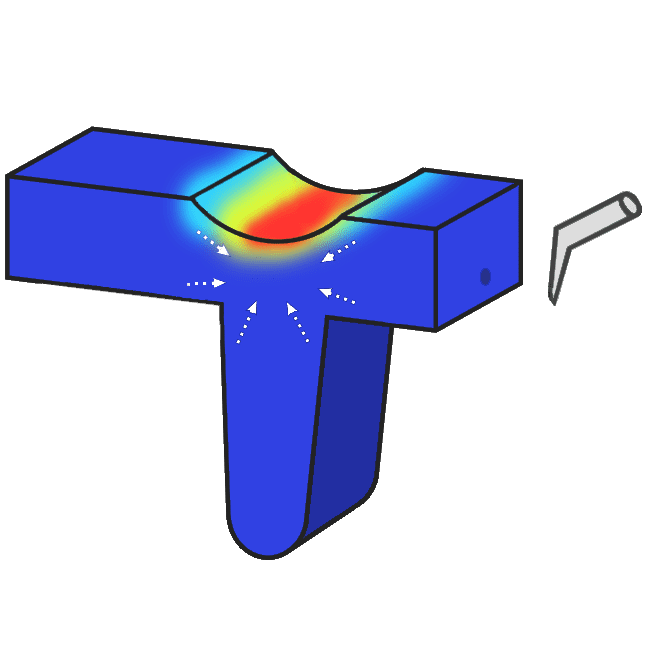

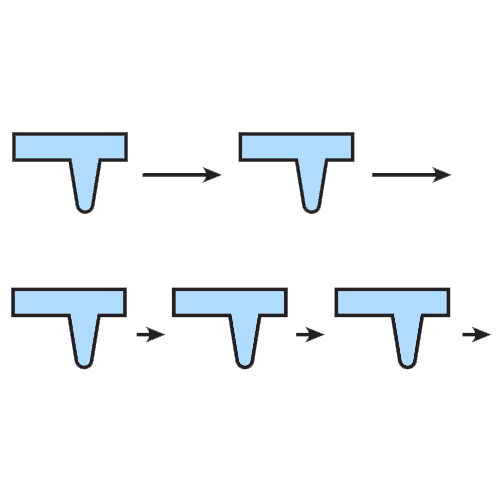

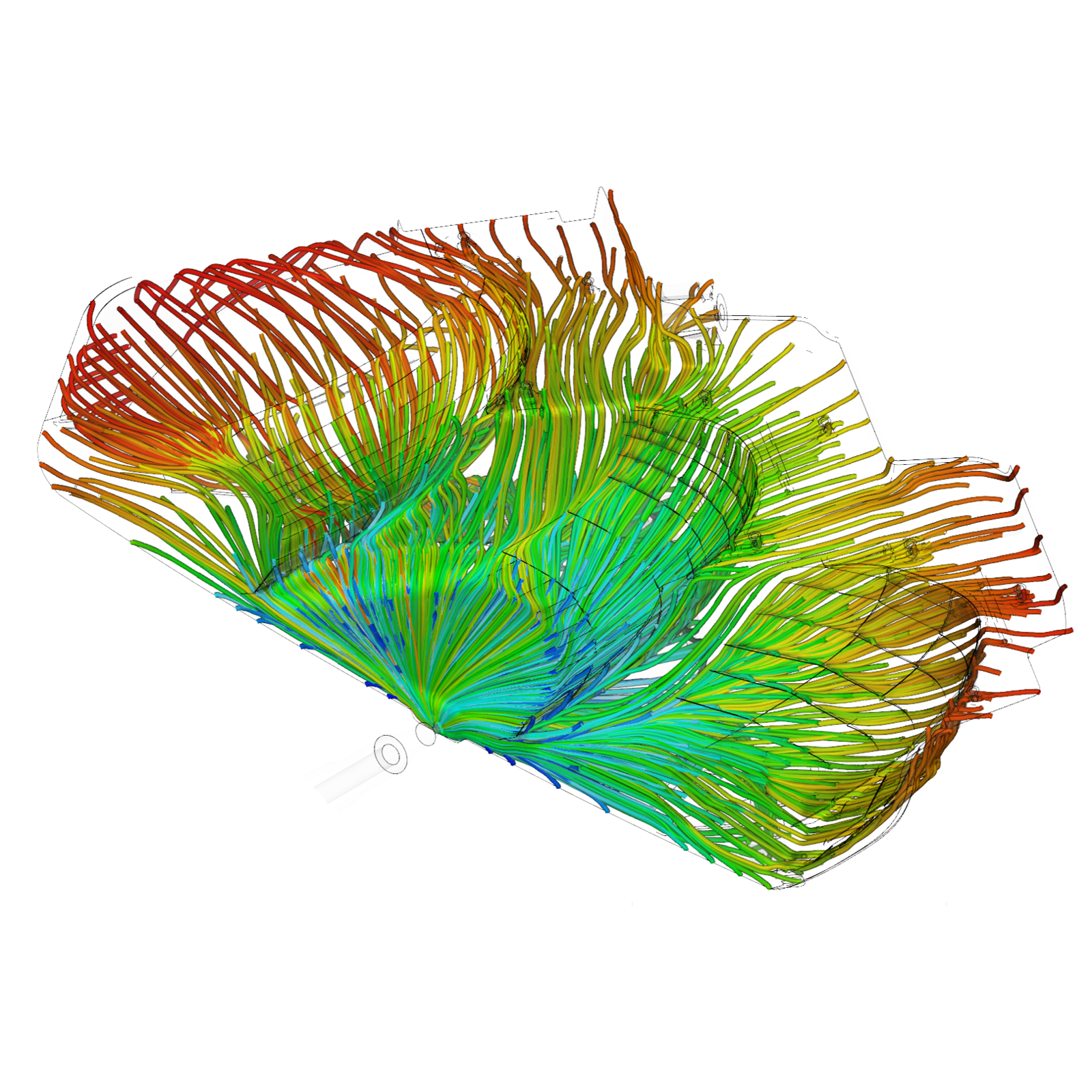

Plastic flow

"A quality product starts with optimizing the flow inside the mold." -SM2

With the flow analysis you will see what is happening inside your mold. Solution M2 offers you to target possible problems before it is too late or expensive.

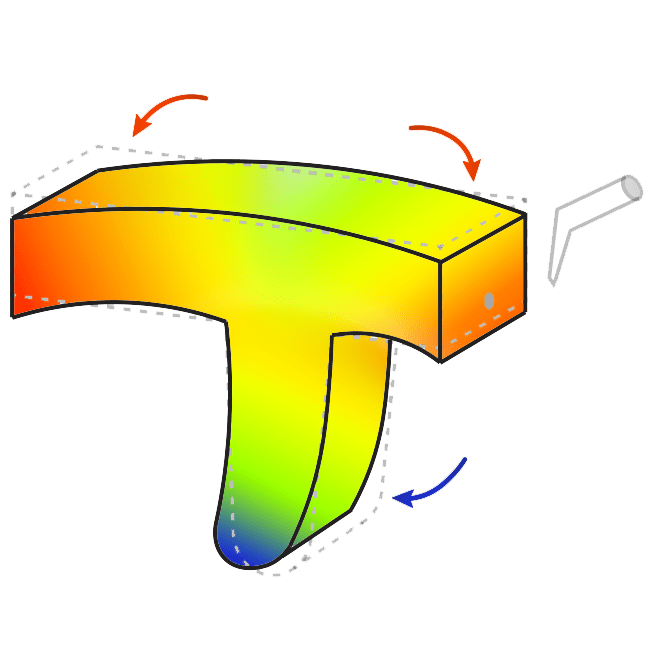

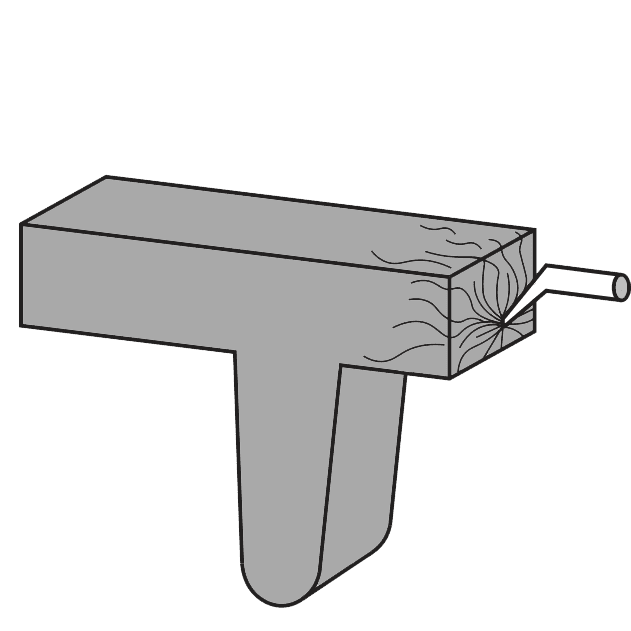

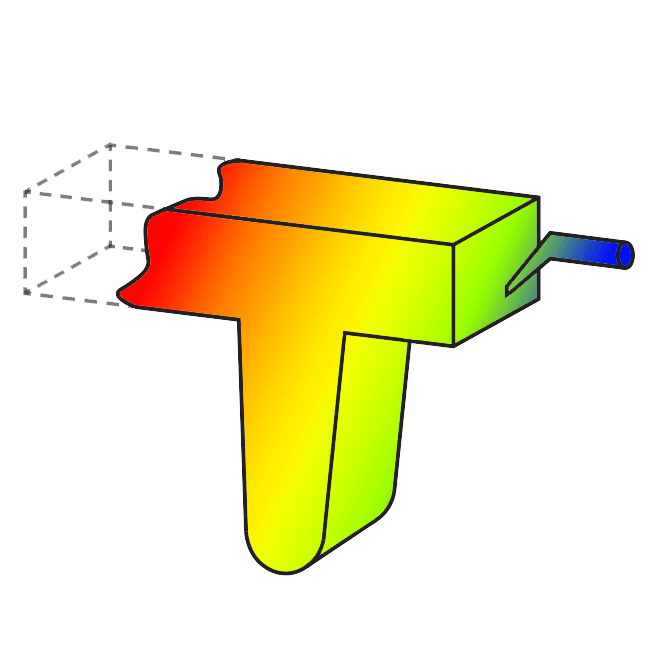

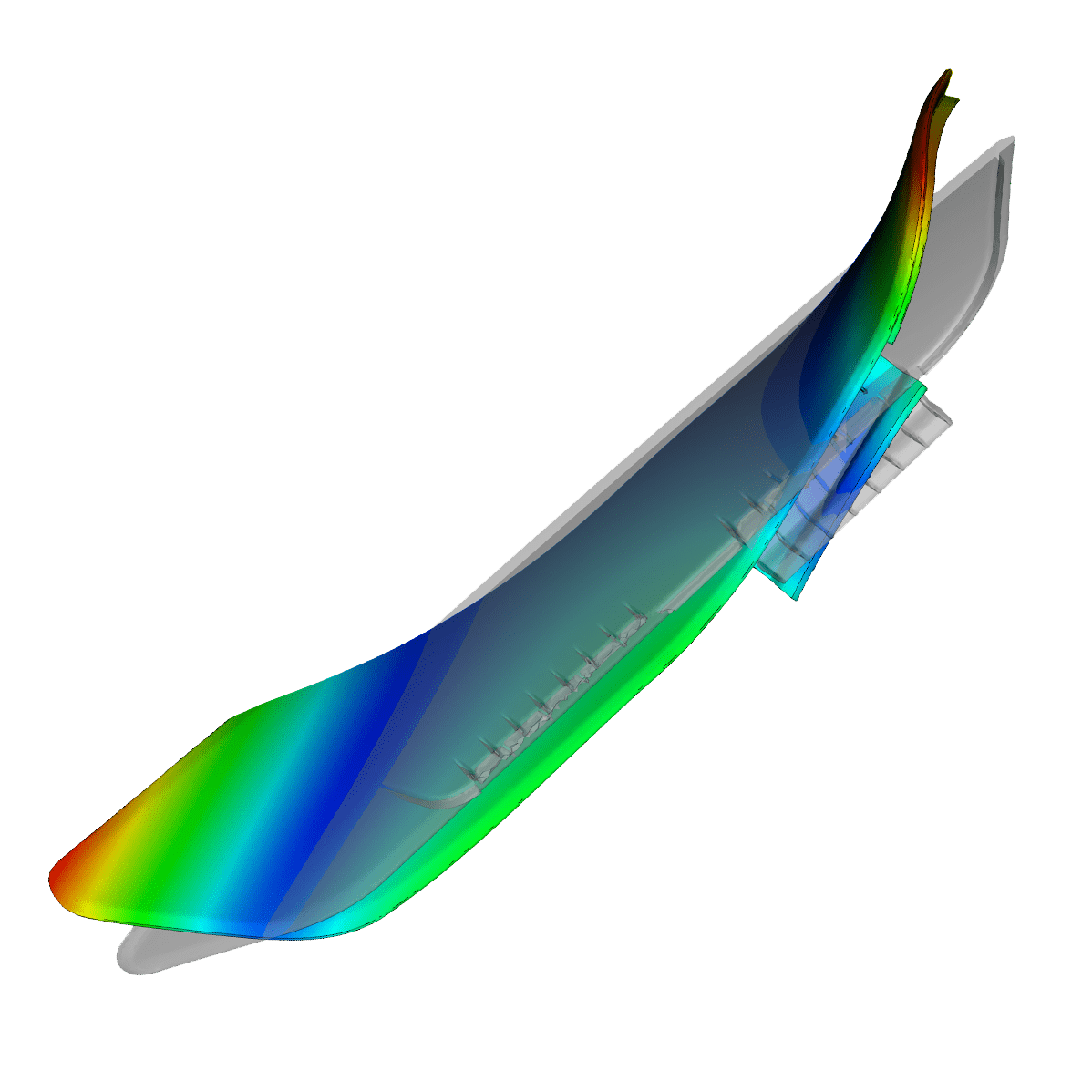

Part warping

Deformations can be a critical element in the production of plastic parts. Will it meet the established design criteria and tolerances?

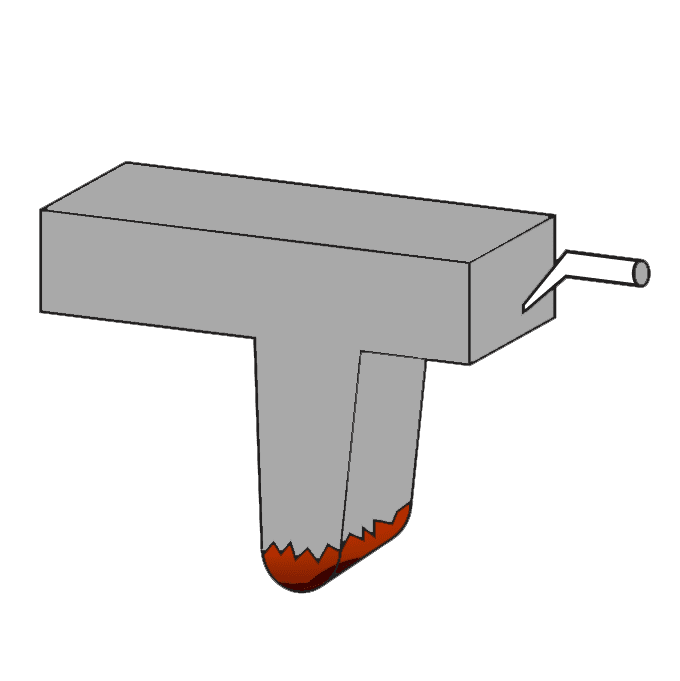

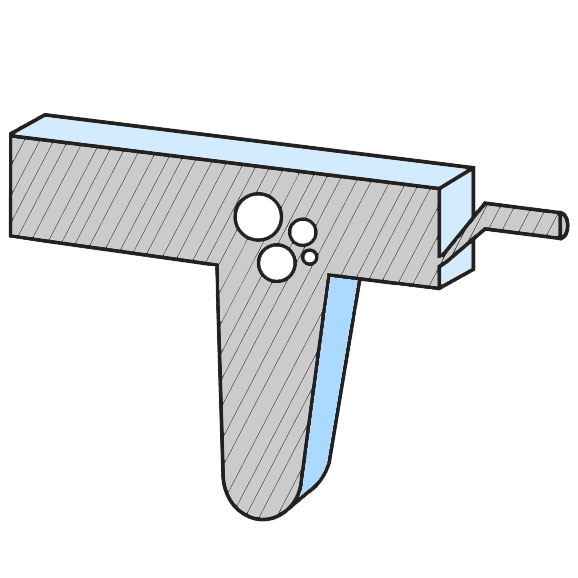

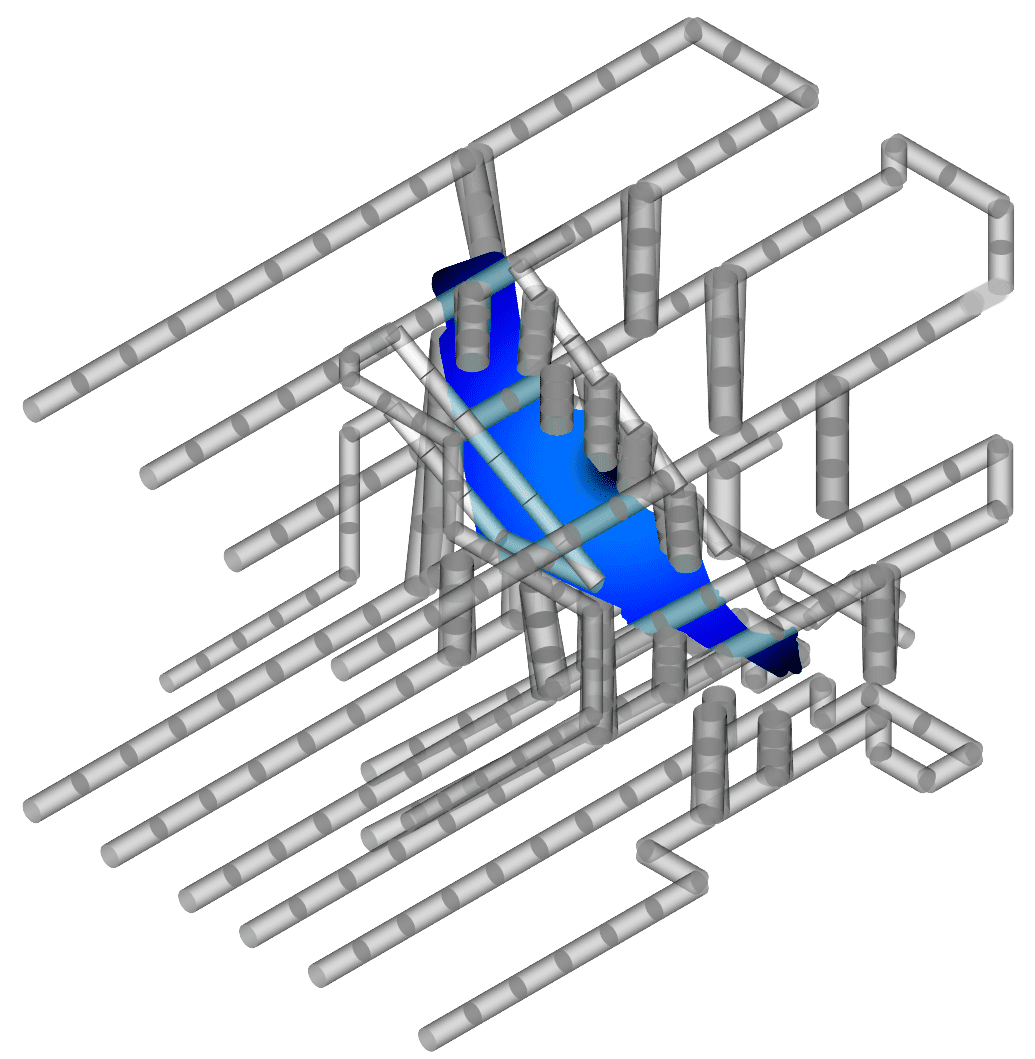

Mold cooling

The part should define optimal mold cooling. This way, many problems can be avoided. Too many cooling lanes? Not enough lanes? Choice of steels?

Cooling gives a lot of optimization information as well as complete tooling for the production of plastic parts.

Leading Application Fields

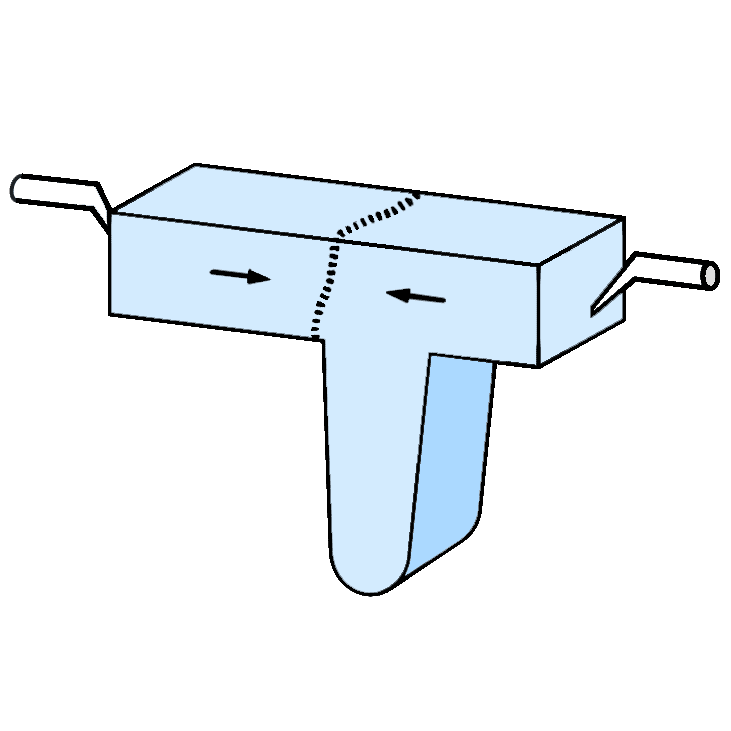

We know that this industry has strict criteria. Nowadays, there are hardly any automobile plastic parts made without a mold flow. Therefore, there are benefits found in using simulations. Now it is one more tool in their toolbox...

Using almost the same type of parts and materials as automotive, this industry seeks to offer excellent quality products. Deformations could prevent a good assembly. It is essential to follow the right recipe depending on the plastic part? Solution M2 is here to answer your questions...

Often the production of these types of products is very challenging. The complexity of the parts often leads to difficulties. Solution M2 can support you with its expertise in the field of large plastic parts...

Optimization would allow a simple approach for obtaining the best configuration of the desired product. Despite the fact that these products are overlooked, Solution M2 knows the market is fierce. Reduced material usage, cycles optimization, etc...